Introduction

In the fast-paced supply chain world of today, accuracy, efficiency, and safety are essential. Delivery delays, workflow disruptions in warehouses, and an increase in operating expenses can all result from loading and unloading delays. Conventional manual tracking of dock activities frequently results in safety hazards, idle time, and misunderstandings. This is the role of smart dock management, a technologically advanced solution that revolutionizes warehouse operations by offering automation, real-time visibility, and useful information.

Real-Time Dock Operations: The Backbone of Efficiency

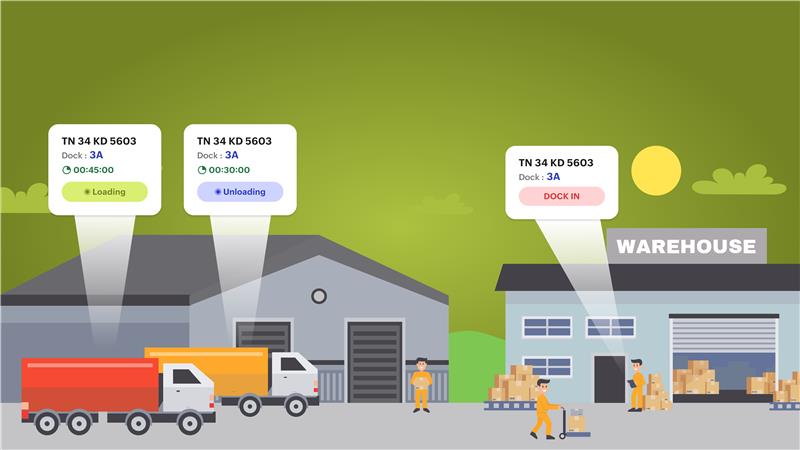

Real-time updates on dock activity are provided by smart dock management.

- Drivers, logistics personnel, and warehouse managers may view which docks are open, which are being used, and when they will be free.

- By doing this, uncertainty is removed, traffic is avoided, and human and mechanical resources are used as efficiently as possible.

- Real-time monitoring enables warehouse staff to make plans in advance, distribute resources effectively, and guarantee a seamless movement of items throughout the building.

- Making decisions for dock operations using a single source of truth improves efficiency, accuracy, and speed.

Key Benefits of Smart Dock Management

1. Shorter Turnaround Period: Automating scheduling and monitoring dock occupancy reduces waiting times for trucks and speeds up loading and unloading processes. This enables warehouses to adhere to tight delivery schedules.2. Enhanced Coordination: Overseeing several trucks at once is difficult. Without depending on manual procedures, staff may efficiently distribute resources, prevent conflicts, and expedite operations using smart dock management.

3. Increased Security: By keeping employees and drivers informed about ongoing activities, automated alarms and monitoring lower the chance of accidents and guarantee adherence to safety rules.

5. Smooth Integration of Systems: Enterprise resource planning (ERP) software, warehouse management systems (WMS), and other logistics tools can all be integrated with smart dock solutions. End-to-end efficiency is made possible by the creation of a single operational ecosystem where information flows freely.

Industries That Benefit from the Dock Application

1. Retail & E-commerce: Quicker unloading guarantees timely delivery and stocked shelves, which raises consumer satisfaction.2. Chemicals, oil, and gas: Real-time tracking guarantees that hazardous chemicals are handled safely and that regulations are followed.

3. Pharmaceuticals & Healthcare: Vital medical equipment, vaccinations, and supplies are tracked to reduce delays and guarantee on-time delivery.

4. Food and Drink: Products that are sensitive to temperature are managed effectively, minimizing spoiling and preserving quality.

Converting Warehouses into Intelligent Infrastructure

Smart dock management is an operational tool that is used strategically and goes beyond simple tracking. Real-time updates, automated notifications, and integration with management systems enable warehouses to function more efficiently, safely, and intelligently. Businesses using this technology can anticipate lower operating expenses, increased customer satisfaction, safer operations, and better use of resources.

Conclusion

Operations in warehouses are being revolutionized by smart dock management. Warehouses may greatly increase production, safety, and efficiency by integrating visibility, automation, and actionable analytics. Putting such technologies into practice is essential to developing intelligent supply chain operations that are prepared for the future.

Visit mawalog.com/dock or get in touch with support@mawalog.com to learn more about how Mawalog Dock may improve your warehouse operations or to begin utilizing the product.