Introduction

Logistics is essential to the oil, gas, and chemical industries because it guarantees the safe, efficient, and economical movement of valuable goods. Dock operations are one of the most important yet sometimes disregarded components of this supply chain. As digital solutions have grown in popularity, businesses are now using sophisticated dock management systems to increase overall productivity, optimize scheduling, and enhance visibility.

About Dock Efficiency in Oil, Gas & Chemical Logistics

The smoothness and effectiveness of loading and unloading operations at establishments like distribution centers, chemical factories, and refineries is referred to as dock efficiency. Effective dock operations are crucial in sectors that handle time-sensitive and hazardous products for the following reasons:

- Timely deliveries to prevent delays in production.

- Safety adherence to legal requirements and industry norms.

- Reduced wait times for tanks and trucks.

- Resource optimization, which guarantees efficient utilization of personnel and equipment.

- In order to offer real-time visibility, predictive scheduling, and automated workflows, contemporary dock management tools link with ERP, warehouse management, and transportation systems.

Real-Time Use of Dock Management Applications

In oil, gas, and chemical logistics, a dock management program promotes real-time efficiency in the following ways:

1. Effective Scheduling & Reservation of Slots- By digitally reserving dock spots in advance, carriers may minimize congestion.

- No two tankers are scheduled at the same berth at the same time thanks to automated allocation.

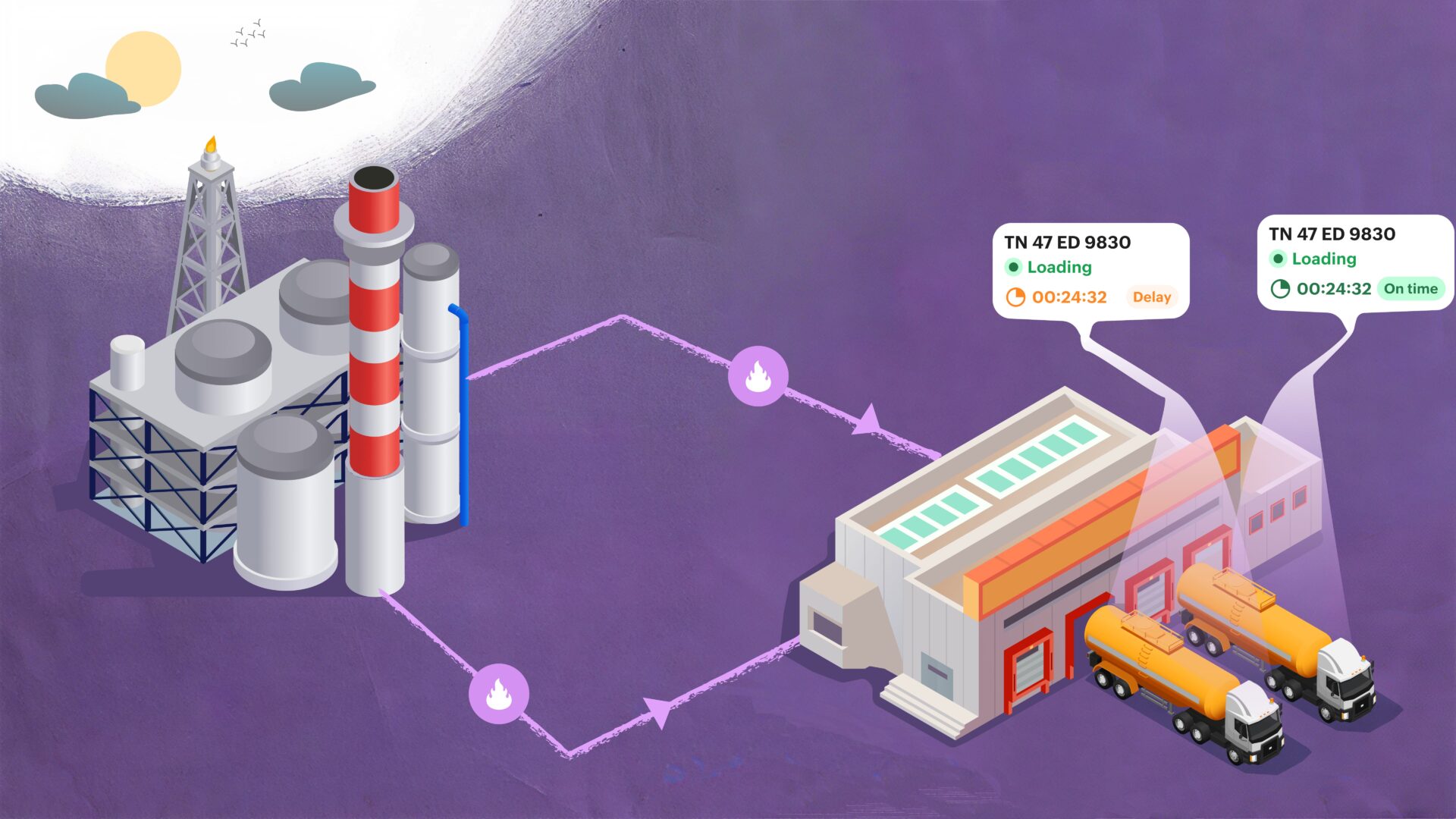

2. Instantaneous Visibility

- In real time, supervisors may keep an eye on truck arrivals, loading progress, and departures.

- Live dashboards make it easier to quickly spot delays or safety hazards.

- Only approved personnel and vehicles are permitted, thanks to the system.

- Digital checklists guarantee adherence to laws governing the handling of dangerous materials.

4. Data-Based Decision Making

- Unused docks, frequent delays, and peak traffic hours are examples of patterns that can be found using historical data.

- Planning for upcoming activities is enhanced by predictive analytics.

5. Automation and IoT Integration

- Temperature, loading times, and tank levels can all be monitored via IoT-enabled sensors.

- Managers are notified of deviations by automated notifications, which guarantee prompt remedial action.

An Action Example

Using a dock management tool at a big petrochemical plant enhanced safety compliance, cut average truck waiting times by 35%, and gave plant managers and logistics partners real-time visibility. Operations ran more smoothly, demurrage expenses decreased, and customer satisfaction increased as a result.

Conclusion

In the logistics of oil, gas, and chemicals, effective dock operations are now required rather than an option. Businesses may guarantee prompt, secure, and efficient operations while cutting expenses and hazards by implementing sophisticated dock management software. Contact us at support@mawalog.com if you have any questions or would want to learn more about how might assist your company in achieving more intelligent dock management.